Digitalization in the optical industry: IP strategy for networked production in the smart factory

Schneider from Hessen is one of the world’s leading manufacturers of processing machines for spectacles and precision optics. Schneider is an innovation driver in the highly complex free-form processing of glass lenses and the associated process technology. Industry 4.0 focuses on increasing resource efficiency and increasing production flexibility.

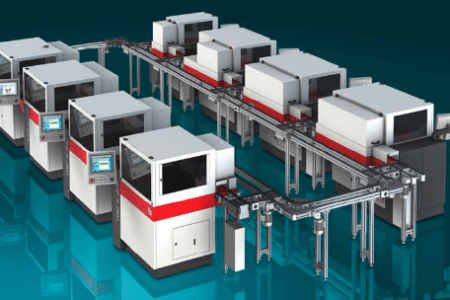

Mechanical and plant engineering plays a key role in the implementation of the smart factory in Germany. As a leading factory supplier, the industry is the enabler for the necessary digitalization and integration of technologies in products and processes. The high degree of customization in the manufacturing of progressive lenses is a major challenge in terms of process technology and costs. With the Modulo concept, Schneider has introduced the Industry 4.0 logic into the production of batch size one free-form glasses. Modulo stands for the move away from linked individual machines in favor of an intelligent network in the form of a higher-level production system that independently manages and optimizes the production flow.

The case study from the master’s program for Intellectual Property Law and Management (MIPLM) of the CEIPI at the University of Strasbourg describes the realignment of Schneider’s IP strategy towards the customer benefit in the B-to-B business. The aim is to achieve an enforceable unique position with regard to the customer-relevant benefits of the Modulo concept on the international markets. Based on the USP, the Unique Communication Proposition (UCP) was designed and made exclusive through the IP position. The methodical anchoring of IP design in the Schneider process landscape ensures that the technical creativity of the employees can be used in a targeted and systematic manner to design the necessary prohibition rights.

Authors of the case study:

Gunter Schneider

Gunter Schneider is the president of the SCHNEIDER GmbH & Co. KG which he founded in 1986. The company is one of the world’s leading manufacturers for the development and production of machines in the fields of ophthalmics, precision optics and ultra-precision optics. Finding its origin in the development and manufacture of optical precision machinery the company creates innovative CNC-driven manufacturing technology for grinding, polishing, measuring and centering of spheres and aspheres. Today, SCHNEIDER is a full solution provider offering comprehensive solutions ranging from small individual machines to complete fully-automated production lines for small, medium and large lens producing labs. The independent, family-owned holding has 13 subsidiaries and employs more than 400 employees worldwide.

Gunter Schneider is a member of the executive board of the German Competence Center for Ultra Precise Surface Processing. Furthermore, he is engaged in various social initiatives and is politically active in the supervisory board of the district president.

Prof. Dr. Alexander J. Wurzer

Dr. Wurzer is Professor for IP Management at the Centre for International Intellectual Property Studies (Centre d’Etudes Internationales de la Propriété Industrielle, CEIPI) at the University of Strasbourg, where he has been programme leader for the Master’s degree in Intellectual Property Law and Management (MIPLM) since 2007. He is Director of the Steinbeis Transfer Institute for Intellectual Property Management at Steinbeis University Berlin and Managing Partner at WURZER & KOLLEGEN GmbH, a consulting firm for strategic IP management.

Prof. Dr. Wurzer is Chairman of the DIN committee for the standardization of patent valuation (DIN 77100). He chairs the Board of Directors of “Deutsches Institut für Erfindungswesen e.V.” (D.I.E.), is Spokesman of the Board of Trustees of the Diesel Medal Awards, Fellow at the Alta Scuola Politecnica at Milan/Turin Polytechnic and Conference Chairman of IP Service World. He is also a member of the group of experts on “IP Valuation” of the European Commission and an internationally recognized expert for IP valuation, especially for FRAND topics and licensing transactions.

MIPLM Case Study Schneider