Control and switchgear construction 4.0: Rittal secures a central position in the networked industry of the future with IP

Through consistent digitalization, Rittal achieves many goals that previously seemed hardly possible. The acceleration of processes in control and switchgear construction, the increase of profit margins, the reduction of personnel costs and the reduction of delivery times are made possible by digitalization at Rittal. The company is countering the enormous cost pressure in the industry by digitalizing the entire value chain and securing this position for itself through IP.

In modern switchgear and control engineering, the digital transformation of the value chain of the Friedhelm Loh Group, to which Rittal belongs, is a showcase for Smart Factory as the implementation of the basic idea of Industry 4.0.

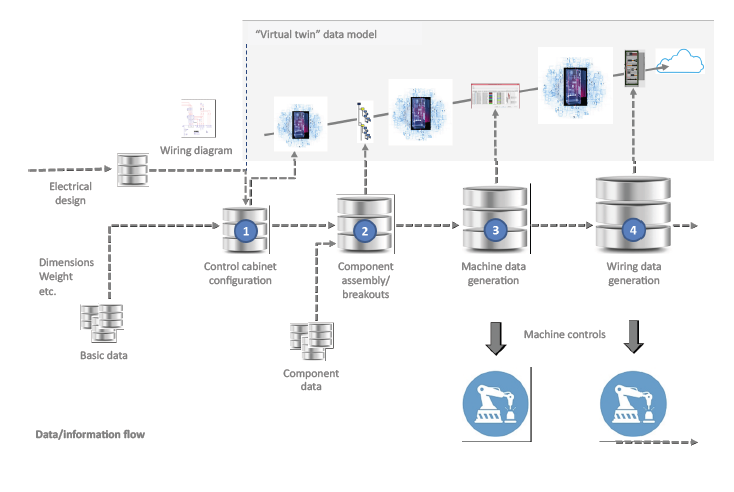

Continuous digitalization and virtualization enables the constant expansion and improvement of automation as well as an increase in flexibility for batch size 1. This includes major increases in efficiency at all levels of the value chain, especially in the assembly of switchgear and control systems. The digitalization of the value chain is an enormous challenge on the IP side. On the one hand, it is important to ensure the freedom to operate a digital business model despite significantly higher innovation and patent dynamics and, on the other hand, to identify the central points in order to make the specific implementation of the value chain for Rittal exclusive. Building on this, the factors that enable Rittal to offer industry-wide USPs must be secured. Using the IP design method, the digitalization of the value chain was analyzed, the neuralgic points were identified and finally an exclusivity position in the field of Industry 4.0 was secured for Rittal.

The case study from the master’s program for Intellectual Property Law and Management (MIPLM) of the CEIPI at the University of Strasbourg describes the protection of the digital value chain in control and switchgear construction. The methodical anchoring of IP design in the Rittal process landscape ensures that the technical creativity of employees can be used in a targeted and systematic manner to design the necessary prohibition rights.

Authors of the case study:

Dr. Thomas Steffen

Dr. Thomas Steffen

| 1983 – 1989 | Studies in Mechanical Engineering RWTH Aachen University |

| 1990 – 1996 | Research Associate, Laboratory for Machine Tools and Production Engineering RWTH Aachen University |

| 1989 – 1994 | Studies in Business Administration at the Fernuniversität in Hagen (German Open University) |

| 1996 – 2001 | Head of Quality Management Flender GmbH |

| 2001 – 2003 | Vice President Quality Management Rittal GmbH & Co. KG |

| 2004 – 2007 | Senior Vice President, International Quality Management Rittal GmbH & Co. KG |

| Since April 2007 | President International R&D and Quality Rittal GmbH & Co. KG |

Prof. Dr. Alexander J. Wurzer

Prof. Dr. Alexander J. Wurzer

Dr. Wurzer is Adjunct Professor for IP Management at the Center for International Intellectual Property Studies (Centre d’Etudes Internationales de la Propriété Industrielle, CEIPI) at the University of Strasbourg, where he has been Director of Studies for the Master’s degree in Intellectual Property Law and Management (MIPLM) since 2007. Prof. Dr. Wurzer is Director of the Steinbeis Transfer Institute for Intellectual Property Management at Steinbeis University Berlin. He is Managing Partner at WURZER & KOLLEGEN GmbH, a consulting firm specializing in strategic IP management.

Prof. Dr. Wurzer is Chairman of DIN committees DIN 77006 for quality in IP management and DIN 77100 for patent valuation. He is a member of the Board of Directors of “Deutsches Institut für Erfindungswesen e.V.” (DIE), Spokesman of the Board of Trustees awarding the Diesel Medal and Fellow at the Alta Scuola Politecnica at Milan/Turin Polytechnic. He is also a jury member for the 2018 German Innovation Award of the German Design Council and a member of the group of experts of the European Commission.