Training at Battenfeld-Cincinnati: Protection of sustainable solutions in the extrusion industry with IP-design

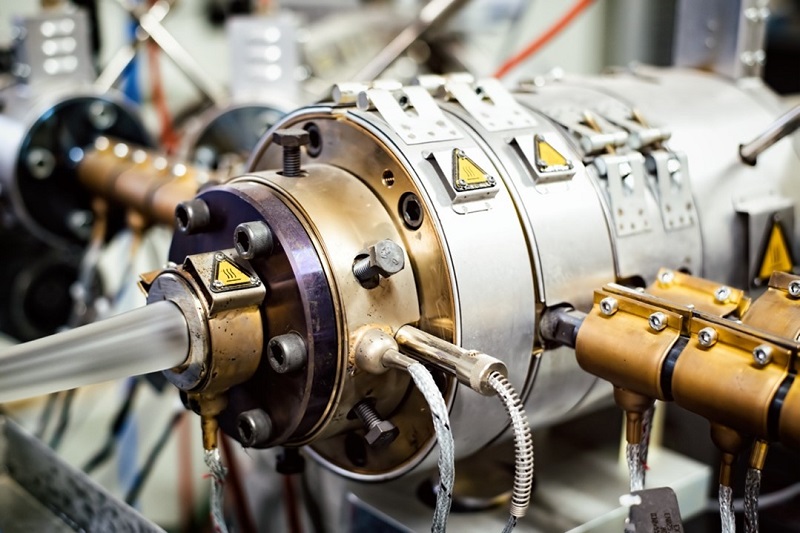

Extrusion is a versatile manufacturing process that involves shaping materials by forcing them through a die to create a continuous profile with a specific cross-sectional shape. This process is widely employed in various industries, including plastics, metals, ceramics, and food processing, to produce a diverse range of products with consistent shapes and dimensions.

The fundamental principle of extrusion revolves around the application of pressure to a material, typically in a semi-molten state, to force it through a specially designed die. The die imparts the desired shape to the material as it exits, forming a continuous length. The extruded material can be solid or hollow, depending on the specific requirements of the application.

Feedback by Dr. Andre Wieczorek, CTO at battenfeld-cincinnati Austria GmbH, after the training:

“The protection of intellectual property is particularly relevant for technology-leading companies. Historically, we at battenfeld-cincinnati have always focussed on mechanical and process engineering topics. The possibilities of protecting digital and software-based solutions has been an area that has received little attention, not least due to a lack of awareness. In particular, the awareness of the given possibilities and the framework conditions to be considered were clearly and comprehensibly presented by Prof. Wurzer through discussions and presentations. Based on the knowledge gained, our company is increasingly considering the possibilities of protecting software-based solutions in the field of extrusion technology.”

Materials that can be used in Extrusion

Extrusion is extensively utilized in the plastics industry to produce a wide array of products, including pipes, tubes, sheets, and profiles. Thermoplastics such as polyethylene, PVC, and polystyrene are commonly extruded.

In metal extrusion, typically performed at elevated temperatures, materials like aluminium, copper, and steel are forced through a die to create complex shapes for various applications, ranging from architectural profiles to automotive components.

Extrusion is employed in the ceramics industry to manufacture items like bricks, tiles, and structural components. The process allows for precise shaping of the ceramic material before firing.

The extrusion process is applied in the food industry to produce various products like pasta, cereals, and snacks. Ingredients are mixed, cooked, and extruded into specific shapes, providing a cost-effective and efficient method for food production.

Hot extrusion involves the processing of materials at elevated temperatures, often above their recrystallization temperature. It is commonly used for metals and some plastics, while at cold extrusion materials are processed at or near room temperature. Cold extrusion is often employed for materials that do not easily deform at elevated temperatures, such as certain metals.

With direct extrusion the material is pushed through the die in the same direction as the ram (the device applying force). This is a common method in metal extrusion.

Indirect Extrusion: In this method, the material is forced through the die in the opposite direction to the ram. This can offer certain advantages, such as improved grain structure in metal extrusion.

Continuous Extrusion: The process is ongoing, producing a continuous length of the extruded material. This is common in the production of plastic pipes and profiles.

Different applications of extrusion:

Extrusion is extensively used in the production of plastic items such as pipes, tubes, sheets, and films. The process allows for cost-effective and high-volume manufacturing of these essential products. In the construction and automotive industries, aluminium extrusions are widely employed to create lightweight and structurally efficient components, including window frames, railings, and automotive parts.

Extrusion is a vital process in food manufacturing, enabling the production of items like pasta, breakfast cereals, and snack foods with consistent shapes and textures. The ceramics industry relies on extrusion for the production of bricks, tiles, and other structural components.

Extrusion is commonly used in the creation of metal profiles for various applications, including structural components in architecture and transportation.

While extrusion offers numerous advantages, such as cost-effectiveness and the ability to create complex shapes, it is not without challenges. Controlling material flow, preventing defects, and ensuring uniformity in the extruded product require careful consideration of factors such as temperature, pressure, and die design.

In conclusion, extrusion is a versatile and widely utilized manufacturing process with applications across diverse industries. From shaping plastic products to producing metal components and food items, extrusion plays a crucial role in modern manufacturing, providing an efficient and cost-effective method for creating a wide range of products with consistent shapes and dimensions.

About Battenfeld-Cincinnati: Sustainable Solutions Worldwide

As technology leader in the extrusion industry, the Battenfeld-Cincinnati Group offers solutions for a wide range of applications – as standard, and in the form of individual, customized solutions. Established in the 1940s, they are one of the oldest companies in their sector, and the only one specializing exclusively in extrusion.

With about 600 associates at five locations in Germany, Austria, China and the USA, they are global players, reliable and close to their customers. Battenfeld-Cincinnati develops, designs and manufactures extrusion lines for companies from a great variety of industries – from the construction industry to water management.

The motto “Sustainable Solutions Worldwide” also stands for the promise to ensure maximum output, cost efficiency and energy efficiency in every project. They are firmly committed to sustainability, to secure a future with an environment worth living in for the next generations. At the same time, they aim to supply the customers with innovative technology for trouble-free production tomorrow, too. This is why they continuously invest in research and development – to create even more efficient processes, while never losing sight of the protection of our environment. How to protect such sustainable solutions with IP-design was also the topic of a training by Prof. Alexander Wurzer at Battenfeld-Cincinnati on 26.01.2023.

How Battenfeld-Cinccinati supplied a niche market

The world’s largest thermoforming line with a footprint of 20 square meters, which transforms about 3 mm thick, extruded, HI-semi-finished PS sheet into what is known as ebb & flow trays for greenhouses. To produce the up to 8 m long and 2.5 m wide semi-finished boards, Battenfeld-Cincinnati Germany, Bad Oeynhausen, installed an ultra-modern sheet extrusion line with throughput rates of up to 3,000 kg/h just under a year and a half ago. The rising world population and the resulting added demand for flowers, shrub and vegetable seedlings for professional and amateur gardeners, fresh herb pots for modern kitchens and the increasing cultivation of cannabis are all contributing to the booming greenhouse and hothouse construction.

Become a certified professional and learn about the protection of sustainable solutions and IP Design in the Certified university course IP and Industry 4.0.