How to transform an IP strategy into the digital realm? New research project at the MIPLM

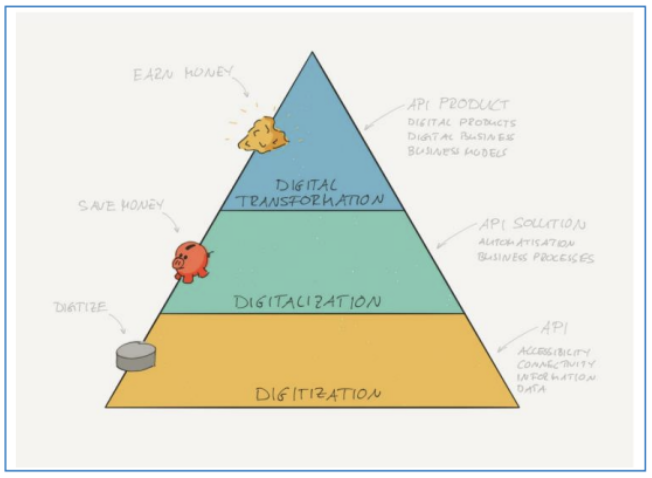

When manufacturing companies undergo the digital transformation, is there a kind of blueprint which they can follow to transform the IP strategy and operations into the digital paradigm? This is the question of the following research project. Machine/tooling manufacturers have a strong “hardware” legacy and skillsets which are mostly related to physical products. The rise of cyber physical systems and digital platforms poses a challenge and threat to these companies but is at the same time an opportunity.

This Thesis proposes a generic blueprint how to determine a value driven IP strategy in this context. This blueprint seems to best fit to machine manufacturing companies which are leading in their markets and therefore are eager to protect or even further expand this position and are ready to invest to achieve their digital transformation.

For smaller companies at the lower end of the value chain, the cost/benefit ratio may not be interesting. But certainly, the thought process and some of the blueprint elements may be interesting for every company of the machine manufacturing sector, to at least understand the context and the possibilities, in order to articulate their strategy.

For smaller companies at the lower end of the value chain, the cost/benefit ratio may not be interesting. But certainly, the thought process and some of the blueprint elements may be interesting for every company of the machine manufacturing sector, to at least understand the context and the possibilities, in order to articulate their strategy.

Digital transformation is underlying this blueprint and this thesis has been an opportunity to think through what “going digital” really means and takes, for a business and in particular for IP.

It really is a mindset change, requiring a holistic adaptation in a company, and demanding top class leadership to deal with the resistance to change and find ways to put an ambidextrous organization in place, that provides a fair share of resources and budget to fulfil the corporate objectives.

It is also primarily about “opening up”, pushing business boundaries to respond to changing expectations of customers. To stay relevant for tomorrow´s business reality, organizations should embed eco-systems in their strategy, seek collaboration instead of conflicts, create valuable relationships and eco-systems instead of only thinking how to exclude others.

It is about being ready to share benefits with other partners. As long as the own company largely benefits from accessing or establishing new essential technologies or entering new markets, it should also be fine if competition also gets a share of the profits.

It is about being ready to share benefits with other partners. As long as the own company largely benefits from accessing or establishing new essential technologies or entering new markets, it should also be fine if competition also gets a share of the profits.

Then the role of IP in the business, and the need for an IP strategy supported by systematic IP processes and appropriate resources gets clear: a company needs to own valuable IP to get the best possible seat at the future table, having a leading position in the future knowledge economy, where data is the fuel for new value creation.

New mechanisms are required to manage digital IP and knowledge sharing, and it becomes necessary to appropriately apply and master the full power of all IP rights and tools.

The risk of not adapting and not embracing digital transformation is to get dependent on platforms, not accessing higher profits anymore and loosing customer loyalty.

The task to transform digitally, and to deploy the IP strategy proposed in the blueprint is very complex and may first look overwhelming. Priorities should be defined, IP should get fully integrated and have a voice in the business strategy discussion to focus on where IP can help most, and help from external experts should be sought to acquire the new required digital capabilities step by step.

To conclude and propose an outlook, this blueprint is in its initial theoretical phase and would benefit from being read by experts, ideally tried as well, to assess its practicability and its value, maybe starting as an awareness, educational and training tool get feedback to further adapt and elaborate it where needed.

Finally, it may be worth further investigating how AI (artificial intelligence) can be effectively applied to assist the inventive and IP design process to conduct prior art and technology searches and to help keeping accurate knowledge data bases.

The research project was conducted by MIPLM graduate Christian Slisse and supervised by Prof. Dr. Alexander Wurzer and Dr. Thibaud Lelong both CEIPI.

Christian’s background includes a degree applied sciences engineering and a master degree in plastics engineering. After working at Valeo, a tier 1 automotive supplier and Rexam Healthcare – Nemera, a global medical device molder he’s been working since 2013 at Otto Männer, member of Barnes Group, a high precision tool manufacturing company. Starting as head for R&D for Männer he got increasing responsibilities for IP an Innovation.

Christian’s background includes a degree applied sciences engineering and a master degree in plastics engineering. After working at Valeo, a tier 1 automotive supplier and Rexam Healthcare – Nemera, a global medical device molder he’s been working since 2013 at Otto Männer, member of Barnes Group, a high precision tool manufacturing company. Starting as head for R&D for Männer he got increasing responsibilities for IP an Innovation.

In 2021, Christian undertook the Master of Intellectual Property Law and Management at CEIPI, University of Strasbourg.

Here is a description of the research project: