Current seminars on the IP protection of apps

Apps are playing an increasingly important role in Industry 4.0. Most people know these programs from their smartphones, but apps are also developing into killer applications for industrial applications. Those who want to use the full potential of Industry 4.0 and remain competitive are increasingly relying on a better and consistent customer experience. Apps are key factors here.

It is no longer just a matter of optimizing a single production step, but of optimizing entire value chains within the increasingly networked Industry 4.0. Apps play a central role in the professional integration of a wide variety of applications in order to make advantages and added value available digitally and mobile. The competitive, productivity and profitability advantages of Industry 4.0 can only be developed with a consistently high density of information along the entire decision-making and process chain.

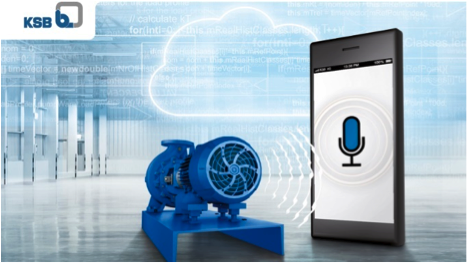

Some examples of IP design show how such apps are developed, integrated, and protected. E.g. at KSB, the Sonolyzer app [Sonolyzer app] can be downloaded onto a smartphone or tablet. This pump app is available for Android and Apple devices and is therefore available on every mobile device. It is the first app that hears whether energy can be saved. With this new app, KSB brings Industry 4.0 directly to the smart end device: Within a few seconds, the KSB Sonolyzer measures the noise frequency of the asynchronous motor and checks whether there is potential for energy savings that can increase pump efficiency. The app uses an algorithm developed by KSB and is so far unique on the market. It can be used not only on KSB pumps, but also on the rotating equipment of many other manufacturers and is of course patented.

Some examples of IP design show how such apps are developed, integrated, and protected. E.g. at KSB, the Sonolyzer app [Sonolyzer app] can be downloaded onto a smartphone or tablet. This pump app is available for Android and Apple devices and is therefore available on every mobile device. It is the first app that hears whether energy can be saved. With this new app, KSB brings Industry 4.0 directly to the smart end device: Within a few seconds, the KSB Sonolyzer measures the noise frequency of the asynchronous motor and checks whether there is potential for energy savings that can increase pump efficiency. The app uses an algorithm developed by KSB and is so far unique on the market. It can be used not only on KSB pumps, but also on the rotating equipment of many other manufacturers and is of course patented.

Apps have very different roles in the various Industry 4.0 and IoT business models. Complex adjustments can be simplified with an app, for example with Hansgrohe’s RainTunes [Case Study RainTunes ]. The app can also be the central point of access to make a certain architecture of the eco-system available to the user, as with 365 FarmNet [Case Study Claas].

Apps have very different roles in the various Industry 4.0 and IoT business models. Complex adjustments can be simplified with an app, for example with Hansgrohe’s RainTunes [Case Study RainTunes ]. The app can also be the central point of access to make a certain architecture of the eco-system available to the user, as with 365 FarmNet [Case Study Claas].

For the creation of smart networked systems, apps are often the central instrument for the practical implementation in industrial reality. This is how the control and optimization of value chains succeeds in real time. In addition, a high degree of individualization of the products with a highly flexible manufacturing and production is possible. In addition, other productivity partners can be integrated into the value-added network.

Apps already have the potential to pave the way for Industry 4.0, because this software-based technology is increasingly revolutionizing the operation and design of applications in the industrial sector. The apps have to be successfully embedded in diverse and challenging scenarios, including in particular the corresponding business models, the concepts, the designs and the software application itself, the security requirements and the IP protection. Because nobody wants to see the investment in the app directly from the competitor, the old truism of computer technology also applies to apps: Nothing can be copied as easily as software.

App-based industrial solutions offer many advantages: As a marketing, service, or sales tool or efficiency-increasing applications for the optimization of productivity, profitability, brand image and, above all, communication with partners and customers. These include:

- to offer new products and services,

- to strengthen customer loyalty,

- to receive and give feedback quickly,

- to provide an individualized service,

- to consult more specifically,

- to optimize the quality,

- to improve internal and external communication,

- to achieve greater flexibility,

- to save time and increase efficiency.

The ThyssenKrupp case study shows how this can be achieved in concrete terms. In order to be able to deliver customized home mobility solutions, ThyssenKrupp relies on the Microsoft HoloLens. The mixed reality glasses enable customers to visualize a stairlift product in their own home in real time. By accelerating various process steps, delivery times are up to four times faster. Microsoft HoloLens is thus becoming an essential tool at Thyssenkrupp when it comes to providing individual mobility solutions at home.

The need for such solutions will increase rapidly: In addition to the growing urban population, better health systems and a higher standard of living also contribute to longer life expectancy. The global population is expected to grow from currently 7.4 billion to over 11 billion by 2100 and to age. In 2016, every eighth person worldwide was over 60 years old. For Germany, the Federal Statistical Office calculates that 69 percent of the population will be in the retirement age by 2060. These figures show that the mobility of older people in cities is a growing challenge.

ThyssenKrupp has already used the Microsoft HoloLens for more than 100 customers in Holland, Spain and Germany with excellent results and positive customer feedback. The next step is the nationwide introduction. A delivery time reduction from approx. 7 weeks to 10 days is already possible. The HoloLens system imports the data directly into ThyssenKrupp’s SAP system and not only enables the sales representative to provide real-time information on costs and delivery times, but the supply chain can also start immediately when the sale is concluded.

At EPLAN, mobile access is granted via apps. Whether commissioning, maintenance, or an error message while the system is in operation: quick action and direct access to the system documentation are required in all cases. EPLAN View Mobile also makes this possible directly on the machine. Available in iOS and Android format, the new app enables direct access to the EPLAN documentation of the automation system and supports the service staff in eliminating faults. The EPLAN Data Portal also visualizes the maintenance need or malfunction directly on the equipment. With the EPLAN Data Portal App, users can access all data available in the portal and search for and select devices or components while on the move. The smart shopping cart transfers the collected data to the original EPLAN project, provided the customer has a software service contract. EPLAN is part of the Friedhelm Loh Group around Rittal and is dealt with in the associated IP design case study [Case Study Rittal] on Industry 4.0 in control and switchgear construction.

At EPLAN, mobile access is granted via apps. Whether commissioning, maintenance, or an error message while the system is in operation: quick action and direct access to the system documentation are required in all cases. EPLAN View Mobile also makes this possible directly on the machine. Available in iOS and Android format, the new app enables direct access to the EPLAN documentation of the automation system and supports the service staff in eliminating faults. The EPLAN Data Portal also visualizes the maintenance need or malfunction directly on the equipment. With the EPLAN Data Portal App, users can access all data available in the portal and search for and select devices or components while on the move. The smart shopping cart transfers the collected data to the original EPLAN project, provided the customer has a software service contract. EPLAN is part of the Friedhelm Loh Group around Rittal and is dealt with in the associated IP design case study [Case Study Rittal] on Industry 4.0 in control and switchgear construction.

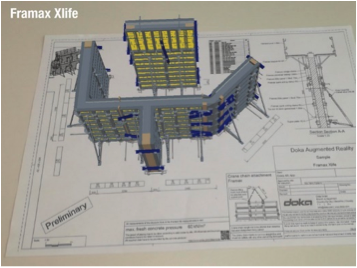

Doka as part of the Umdasch Group [Case Study Umdasch Group Venture] is also working intensively on augmented reality solutions in order to create a unique customer experience. For example, an app from Doka expands 2D planning into 3D models. In 3D planning, a computer-aided 3D model of structural parts and the formwork body is created based on the existing data as the basis for the further planning and production of the special formwork.

The following seminars from current industry practice explain how apps are planned as business model extensions and supplements and protected with IP: